Innovative Wastewater Treatment Plant Design

Design-Build WWTP

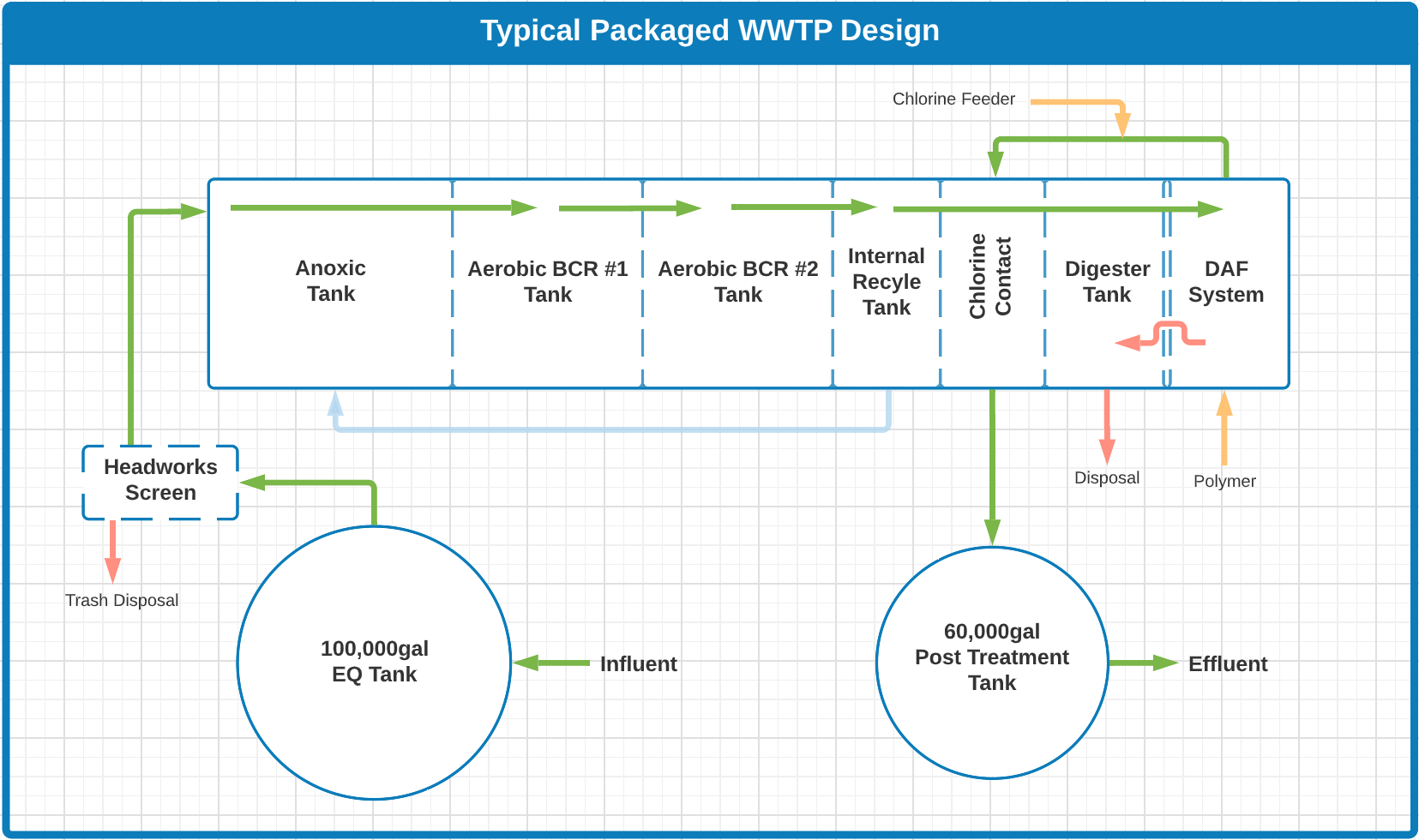

Packaged Wastewater Treatment Plants

Containerized Wastewater Treatment Plants

A Proven Wastewater Process

What We Are Working On

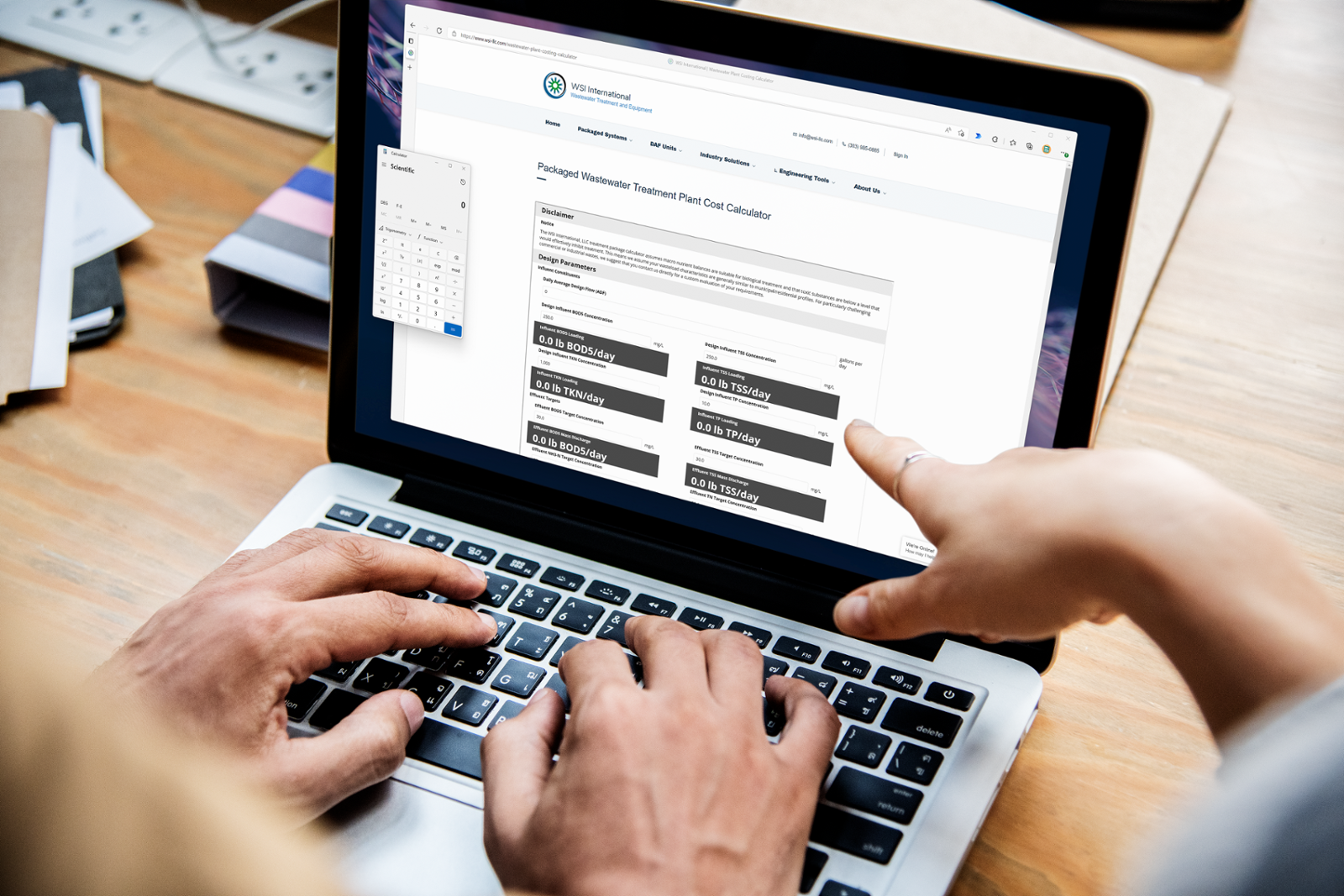

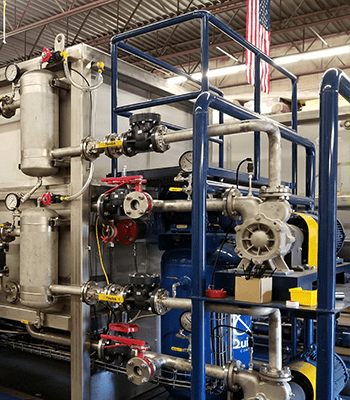

WSI International designs and builds packaged wastewater treatment plants, Dissolved Air Flotation (DAF) systems, and Membrane Bioreactor (MBR) systems. We have a strong presence in industries such as Oil and Gas, Food and Beverage, and Municipal Water, providing innovative and efficient solutions that meet the specific needs of each industry. We also offer DAF rentals for companies in need of a temporary solution. WSI International is known for delivering cost-effective, high-quality wastewater treatment systems that help reduce environmental impact and lower operating costs. Review our posts and connect with us on LinkedIn for the latest updates on our products and services.

Custom Equipment

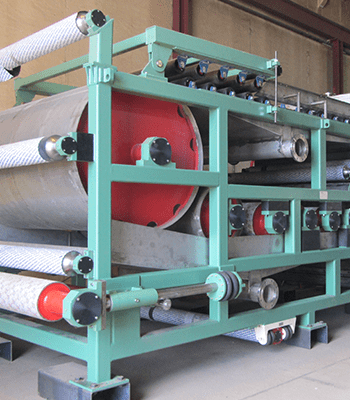

We build dissolved air flotation,

belt presses and coagulation systems

all over the world.

WSI engineers understand the demands of every industry and their wastewater treatment needs. Thus, we help come up with efficient equipment suited to the requirements of your industry – whether Oil and Gas, Food and Beverage, Municipal, Mining, Industrial.

Clients

Meet Our Knowledge Base

Core Technologies

Why choose WSI International?

- Safety & Compliance Ensured

- Start-to-Finish Solutions

- Superior Service

- Sustainable

- Trained Professionals

- On-Time Delivery

- All Stainless Steel Designs

- Reliable Technology

Operational Experience

WSI is well diversified in several markets, including Oil and Gas, Food and Beverage, Municipal and Mining.

Clients

Financing

- Application Only up to $500,000

- Up to $10,000,000 with Financial Package

- Terms 12-84 Months

- Technology & Equipment Upgrades

- 100% Financing

- All Soft Costs Included (Maintenance, Install, etc.)

- New & Used Equipment