Dissolved Air Flotation (DAF) Systems - The Ultimate Solution for Water Treatment

Dissolved Air Flotation (DAF) Systems - The Ultimate Solution for Water Treatment

The Working Principle of DAF Systems

DAF systems work by creating tiny air bubbles that attach themselves to suspended pollutants in the water. The bubbles lift the pollutants to the surface, where they can be easily removed. The process starts with the addition of a chemical coagulant to the water, which causes the suspended particles to clump together. This makes it easier for the air bubbles to attach to the particles and lift them to the surface.

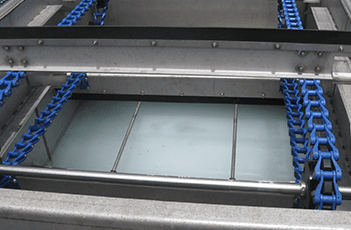

Once the pollutants have been lifted to the surface, they are removed by a skimming device. The cleaned water is then ready for discharge or reuse. The process is repeated continuously to ensure that the water remains free of contaminants.

The Benefits of Using DAF Systems

There are numerous benefits to using DAF systems for water treatment. These include:

High efficiency: DAF systems are highly effective in removing a wide range of pollutants from water. They are capable of removing up to 95% of suspended solids, oils, and grease from water.

Cost-effective: DAF systems are more cost-effective than other water treatment methods, such as chemical precipitation and sedimentation. They are also more energy-efficient, as they use less energy to create the air bubbles than other methods.

Easy to maintain: DAF systems are simple to maintain and require minimal operational attention. They are also easy to operate, making them ideal for use in remote locations where maintenance and repair services may not be readily available.

Environmentally friendly: DAF systems are environmentally friendly, as they do not produce any harmful by-products or discharge pollutants into the environment.

CAD Drawings of Standard DAF Systems

Standard Designs (POC, and Demensional Drawings):

> 50 GPM

± 100 GPM

± 250 GPM

± 500 GPM

< 1000 GPM

VARIABLE

Need Help with a DAF System? We Have You Covered:

Get a Proposal in 24 Hours:

Current Fabrication Time: 8 Weeks or Less!

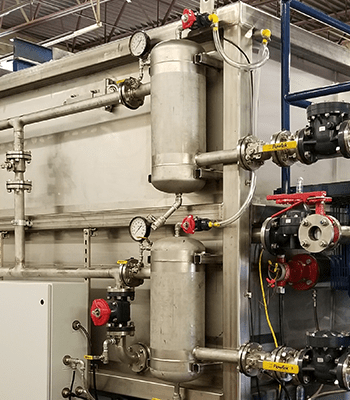

Packaged DAF Systems with Integrated Controls, pH Balance Tank and Sludge Holding Tank

What We Are Working On

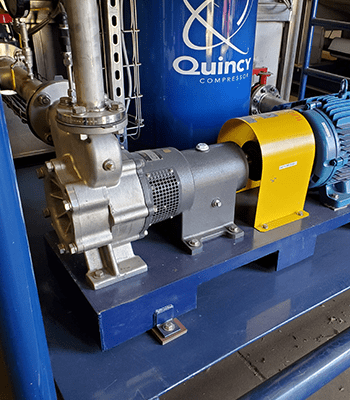

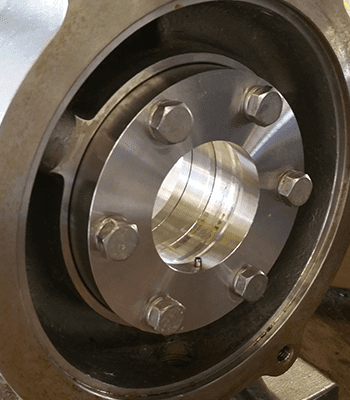

Nikuni DAF Pumps

The Nikuni DAF pump is a high flow micro-bubble generator made from 316 stainless steel. The Nikuni pump is a highly precise pumping mechanism that generates microbubbles by utilizing two hydro-dynamic principles: negative pressure sucking both air and water simultaneously from each port; air effectively mixed into water; which properly produces pressurized nitrogen-enriched discharge.

Micro Bubble Generation

The Micro bubbles generated from the Nikuni pump system are dispersed into the DAF by three to six precisely located white water injectors. These injectors are constructed out of 1.5” schedule 10 304 stainless steel pipe. These pipes run the width of the DAF and have a proprietary grooved design opening for proper distribution and enhanced flocculation. Each injector has a diaphragm valve that will allow the operator to dial in the precise distribution of white water.

The white-water injectors play a crucial role in the DAF system as they are responsible for creating a homogenous mixture of micro bubbles and wastewater. This mixture is then subjected to a flocculation process which leads to the formation of larger flocs. The precise control over the distribution of white water allows for optimal flocculation and maximum separation of suspended solids. The use of 304 stainless steel in the construction of the injectors ensures durability and resistance to corrosion in harsh wastewater environments. The proprietary grooved design of the injectors also enhances the mixing of the micro bubbles and wastewater, leading to improved performance of the DAF system.